CONTACT US

We reply you within 12hours!

We make the quotations within 24 hours!

HC-Mold (Plastic & Metal) International Co., Ltd.

Tel: +86-769-85327002; +86-769-23566161

Fax: +86-769-85391842

Email: [email protected]

[email protected]

Massager:

General Features:

1.Quality Management: ISO9001:2008 & TS16949

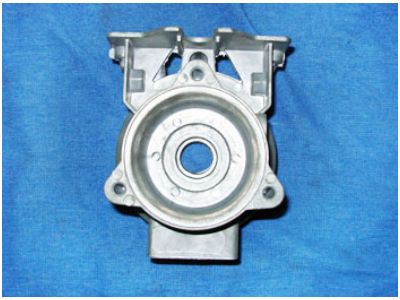

2.Molding Material: Aluminum alloy, A360, A380, ADC 10, ADC 12, ZL102, ZL104, iron, brass, copper zinc etc

3.Tolerance: 0.02mm

2.Molding Material: Aluminum alloy, A360, A380, ADC 10, ADC 12, ZL102, ZL104, iron, brass, copper zinc etc

3.Tolerance: 0.02mm

4. Advantage: High quality, low prices, fast turnaround

5. Application: Quality mass production for your new product development, such as Household appliances, kitchenware, transportation tool, digital & telecommunication products, toys, custom products, auto parts, etc.

Plastic and metal parts life comes from HERE��

|

Process: |

Sand casting, investment casting, die casting, permanent mold casting |

|

Mold Cavity: |

Single, Mult, Family |

|

Molding Material: |

Aluminum alloy, A360, A380, ADC 10, ADC 12, ZL102, ZL104, iron, brass, copper zinc etc |

|

Surface finish: |

Electro-polish, Chrome plating, sandblasting, painting, powder coating, electrophoresis etc |

|

Applicable Industry: |

Auto parts, motor shell, pump parts, machinery parts,lamp chimney etc. |

|

Design software: |

PRO/E.Solidwork,UG.Moldflow.Autocad,etc |

|

Mold Standard: |

JIS, DIN, ASTM, BS |

|

Mold Life: |

10,000~100,000cyces according to your requests |

|

Production Weight: |

0.5kg--50kg |

|

Lead time to T1 sample: |

2~4 weeks |

|

lead-time for production: |

1~2 weeks |

|

Quality: |

ISO 9001:2000 |

|

Precision: |

0.005mm |

|

Service: |

OEM &ODM service. |

Tooling and Injection Molding Sampling Show:

A short overview of HC-Mold's activities:

1. Rapid Prototype Making

CNC, SLA(Stereolithography) and SLS(Selective Laser Sintering), 4~7days lead time.

2. (Export) Mold Making and (Un-Export) Mold

We export Molds for problem-free use, and also make economical molds for use in China-we also have the injection machines for molding production.

3. Parts Production, Final Assembly, Testing and Packaging

To further reduce your cost we produce plastic and metal parts in China further. Assembly is generally the most labor intensive step in the production process, so this is really where we can save you a lot as well.

For RFQ,

please contact with us at any time.